Lift Station Anatomy and Operation

Fox Commercial Services provides a wide variety of plumbing repair and services for our commercial customers. As with most things that work great, lift stations are something you might never consider until they aren’t working correctly. These devices are a critical part of the overall sewage and drainage systems that keep plumbing and sewage disposal systems working around the clock, so it’s hard to imagine life without them…. even for a few hours! This guide is intended to provide you with a basic understanding of how lift stations work and to present suggestions for the routine lift station maintenance and care.

Design

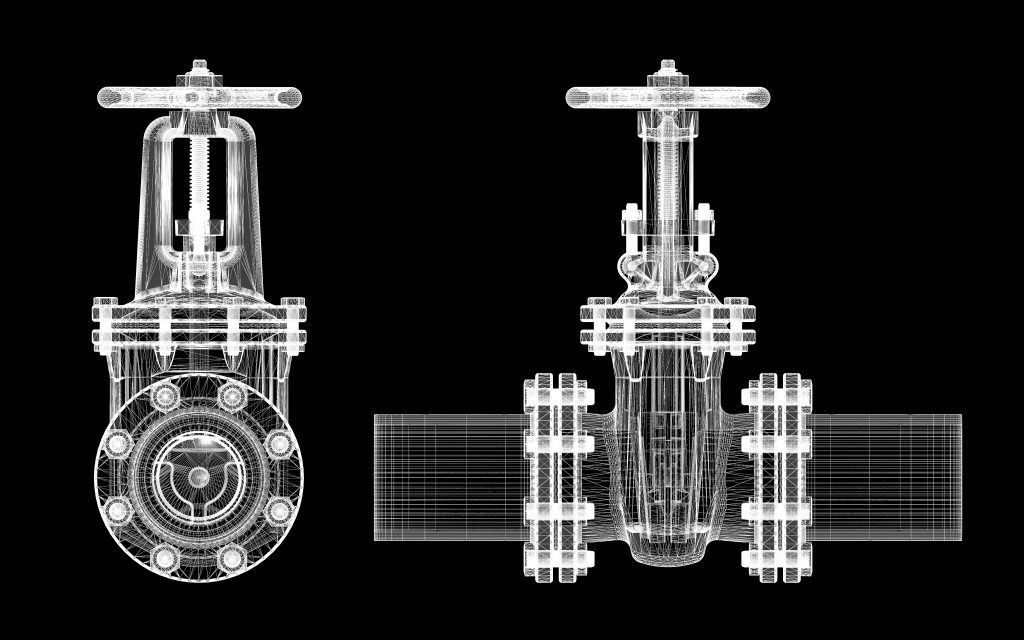

By following these lift station maintenance suggestions, the chances of experiencing a catastrophic lift station failure can be significantly reduced. To begin with, there are two main elements to a lifting station: the wet-well and the controls. The wet-well is a basin that the inflow is discharged into and where the pumps sit. This basin can be made out of steel but is more commonly made of fiberglass or concrete. Usually, there are two pumps in the wet-well, each with their own check valve and shut off valve which flows into the outflow pipe(s). There can be variations to this design including only one pump or multiple pumps to assist in removing the water in the wet well.

Lift Station Maintenance: Check Valves

The check valves stop the pumped water flow from coming back into the wet-well when the pumps shut off and keep one pump from pumping back into the other. A shut-off valve allows for the isolation of each pump and pumps usually sit on disconnects mounted to the floor which have guide rails extending the full depth of the station which allows for individual pumps to be removed and serviced by using a cable or chain without having to enter the station. Furthermore, most stations have a level-sensing device which can take the form of mechanical float switches, a transducer, or both.

Lift Station Maintenance: Float Switches

In the case of float switches, four are typically used. The lowest is called the off float, the next highest is the lead float, then the lag float, and finally the high water/alarm float. The purpose for having these is that in normal operation the pumps switch back and forth after each pumping cycle. An alternator selects which pump will be the “lead.” This pump will turn on when the water level reaches the lead float. The other pump is now called the “lag,” and will turn on if the water level reaches the lag float. At this time, both pumps are now on until the off float is triggered. The next time the lead float is triggered the other pump will assume the “lead” role.

Lift Station Maintenance: Controls

This is a way for the pumps to back each other up in case a problem occurs. A transducer works by varying the amount of DC voltage it sends back to the control panel in relation to the water level in the wet well. Triggering the pumps is most commonly handled through a transducer level controller. The control panel is the brain of the equipment. It contains the circuit breakers, motor starter, overloads, pump controller software (if applicable), and communication devices (if applicable).

The control panel may contain high voltage and phases, so take the necessary precautions to prevent injury. The overload is tripped (causing the pump to turn off) if too much current is drawn by the pump. This can be caused by a dead short, locked pump, water in the motor, an object caught in the impeller, etc. The floats run off a low voltage system and use either the pump controller or a printed circuit that activates the pumps.

Automatic vs Manual Settings

Each pump also has a hand-off-automatic (HOA) switch. The hand position (H) runs the pump (in manual mode) and the automatic position (A) runs the pump off the level sensors. If a single phase system is used the panel would also house capacitors to start and run the pump. Typically, the control panel also displays the pump’s thermal overload protection and seal failure sensors in the form of a light and reset button. These trigger the pumps to turn off if they are tripped. The panels also contain the hour meters and phase protectors (if applicable).

Remember, never assume that the power is off until you have checked it with a voltmeter and do not work on the panel until this is done.

Lift Station Maintenance Tips

The pumps, electronic controls, and electrical works are under constant physical stress, and the corrosive environment requires constant maintenance repair. There is, however, a point where they need to be rebuilt with wholesale equipment replacement. On average that is about every 15 to 25 years. For larger capacity pumps it is recommended to rebuild at least one pump a minimum of every two years. Performance of routine and preventative maintenance can save station’s owner from costly repair bills. The following are suggestions that may ensure fewer breakdowns and problems:

Top 10 Recommendations

- Always make sure the pumps and electronics are de-energized before coming in contact with them to ensure your complete safety.

- Wet wells should be pumped out and cleaned at least twice a year, or more often if necessary, to prevent solids and grease build-up. The build-up of solids can create gases that can damage the pump, or sink and get caught in the impeller.

- Inspection of submersible pumps should be performed quarterly. Inspection of the impeller should be performed quarterly or when motor hours are not within specifications. The inspections would assure that the impeller is free of debris or any other clogging material.

- Inspection and greasing of the check valves should be performed at least twice a year to ensure proper working order and to prevent back-flow from the force main to the wet well.

- Cleaning and inspections of floats four times a year assure proper performance. The buildup of grease prevents floats from working properly.

- Inspection of the light and alarm systems should be performed weekly. An alarm system in working order can alert you to problems immediately.

- Installation of an hour meter on each motor will give one an accurate record of how often each motor is cycling; and hence, the amount of water being pumped through the system. A logbook of motor hours, dates and maintenance performed should be kept.

- Amp readings should be taken at least once a month on each station motor. If the amp readings do not meet the manufacturer’s specifications, it is an indication that debris is lodged in the propeller within the motor, or that water has entered the motor housing or the wiring.

- An inspection of all electrical motor control equipment to find poor connections and worn parts should be performed semi-annually.

- Inspection and cleaning of the basin, clean-outs, and covers should be performed to prevent build-up. In high corrosion prone environments, all moving parts should be operated and greased if necessary to ensure mechanical components are not at risk of failure. Good records can assist in every aspect of a maintenance if there is good record keeping you can instantly determine a problem with the system in some cases. For instance, steadily increasing amp draw or the hours of operation is steadily increasing on one pump and not the other. Records are needed to prove that the system is operating properly and can assist in determining if any future maintenance is required.